Adrià Baró Biosca

Mechanical and Design engineer

Structured and practical Mechanical Engineer with +1 year of experience in designing highly integrated products.

I am a great teamworker when the situation requires collaboration and adjustment between teams. When working alone, I see myself being effective and detail-oriented. Hands-on experience on CAD programs, robust design and rapid prototyping

Have a look at my LinkedIn

Thank you for your visiting this page.

Total visits:

Robustness of Toyota acceleration pedal

DESCRIPTION

This project was one of the three assignments of the Robust Design of Products and Mechanisms course, at MSc level. The course provided a robust design toolbox that allows for an analysis and improvement of the robustness during product development. So to obtain products less sensible to variation effects, improving its quality and reliability.

OBJECTIVES

The objective of the project was to investigate, and try to improve, the robustness of the Toyota acceleration pedal. This pedal was widely recalled for causing many accidents due to (“unintended accelerations”). Also, to use quantitative stack-up analysis as well as specify suitable tolerances so to ensure functionality and producibility.

METHODOLOGY

TOLERANCE ANALYSIS

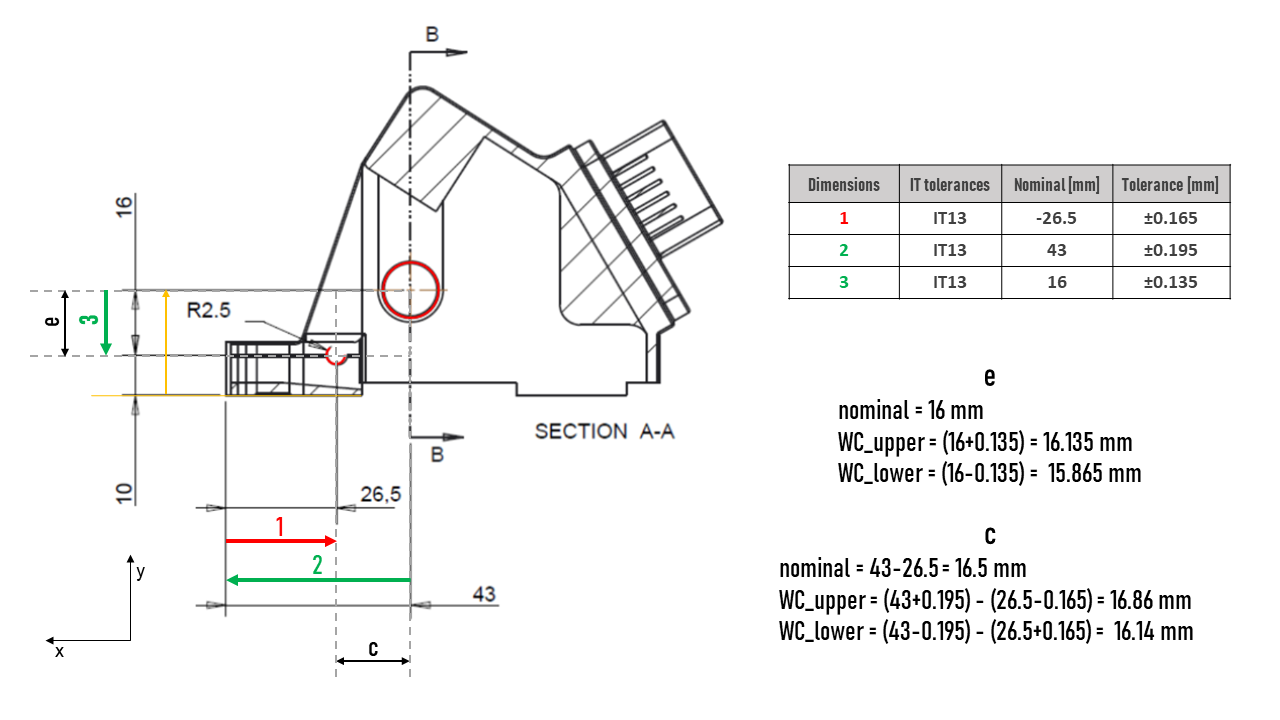

The project started by understanding the acceleration pedal mechanism and with a discussion on possible product failures, variation influences, and part variation. Then, some tolerance, engineering fit and statistical analyses using the production drawings of the acceleration pedal were conducted. An example of tolerance analysis is shown in Fig.1.

A reflection of the tolerances and specifications was included and considered in further steps of the project.

TOLERANCE REDESIGN

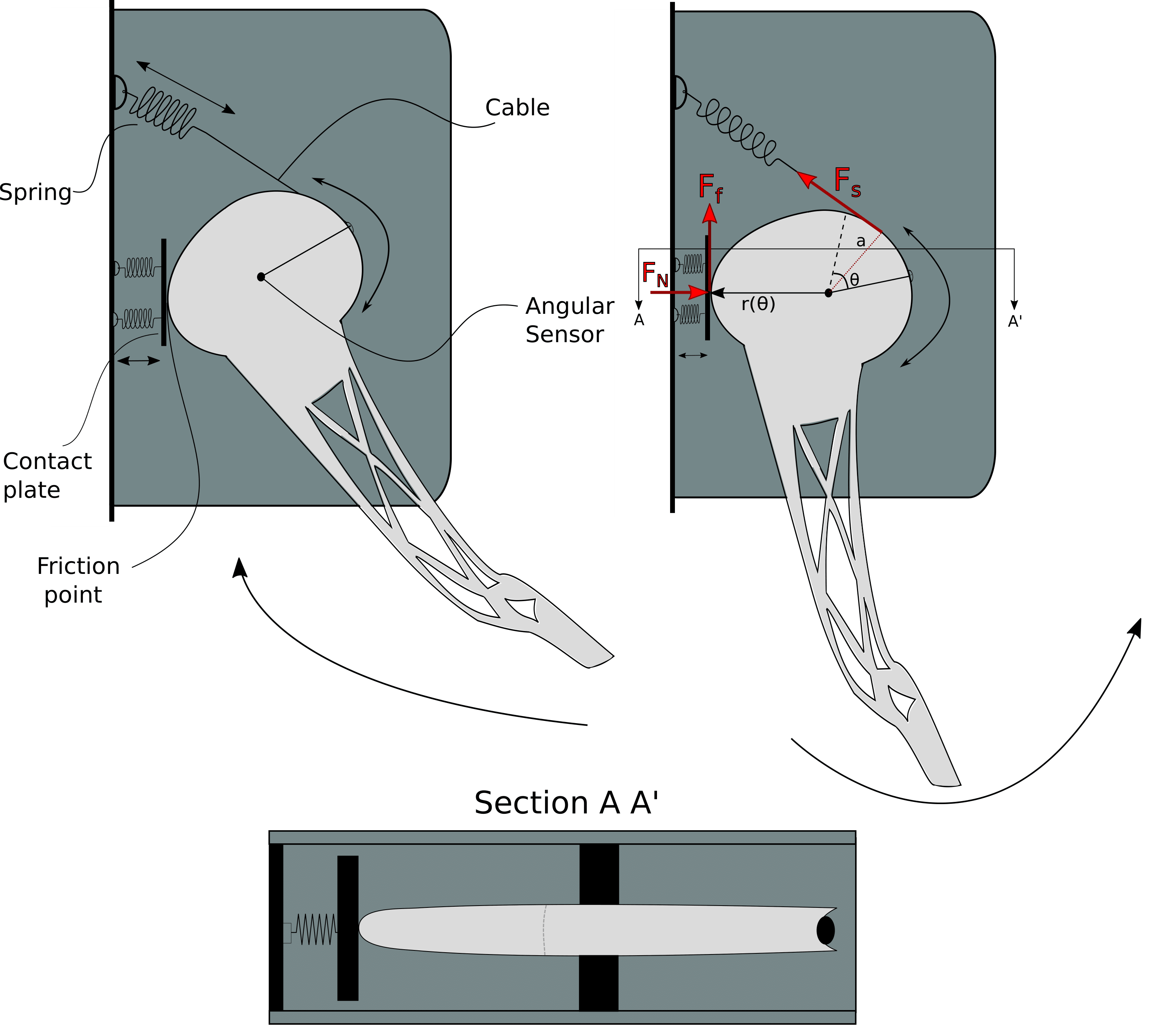

In the second part of the project drawbacks of the current redesign were identified. Using Tolerance Design principles, a redesign of the pedal was proposed to reduce the effect of variation, hence to increase its robustness. The proposed redesign was sketched as displayed in Fig.2.

This redesign, as well as the initial design, were later analysed with a sensitivity analysis. This analysis demonstrated that the redesign was eliminating some sources of variation.

SIX SIGMA ANALYSIS

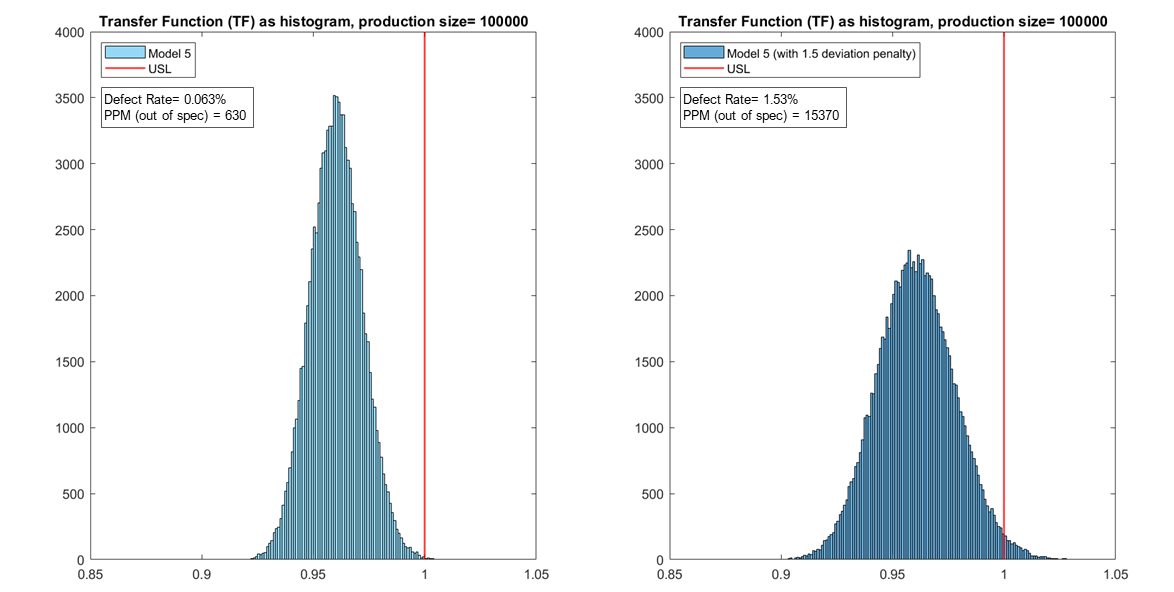

Finally, a Six Sigma approach was used together with Monte Carlo simulations to calculate the number of defects in productions. Different models with different assumptions were simulated. One of the simulations is presented in Fig.3.

CONCLUSIONS

The project offered a great overview of how the robustness of a product can be assessed using different tools. Also, how the sources of variation can be spotted and reduced not only by more traditional methods but also by using Tolerance Design principles.

THE TEAM

This project was performed with four fellow students of the same master. Each of us was involved in all the parts. The members of the team were:

Rasmus Gottenborg Kajbæk

Jonas Weiran Xu

Saeid Pieki

Susana Osborne Valenzuela

PROJECT GRADE: 10/12 (7-point grading scale, ECTS mark=B)

Copyright © 2020 by Adrià Baró Biosca. All rights reserved.